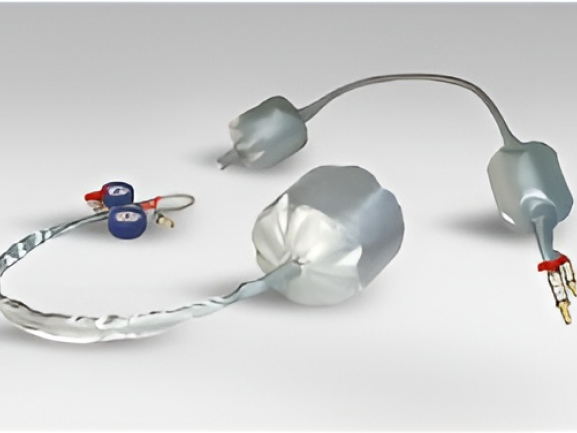

Pneumatic flow-stop bags

Städtler+Beck manual pneumatic flow-stop bags are used to stop the flow of medium in pipelines from DN 40 to DN 2000.

The ball(s) are inserted through a pipe cut or pre-drilled hole into the pipeline in the opposite direction to the section to be shut off and are inflated with air, hermetically sealing the pipeline on its axis.

Flow-stop bags for manual release are indispensable for “unpredictable jobs” with increased danger.

They consist of a ball (single ball) or two balls (double balls) connected to a hose (flexible or metal) with a conical rubber plug at the end, a ball valve and a pressure gauge (or several ball valves and pressure gauges depending on the type and configuration of the flow-stop bags).

WELDING UNDER FORMING GAS

In order to obtain an optimum weld, the oxygen at the welding point must be displaced by the forming gas before welding.

For this purpose, one pusher ball (for welding under molding gas) is used at each pipe end in case of small pipe sections.

The forming gas can be introduced into the pipe section through the ball passage.

The double push ball can be used for welding with molding gas to save inert gas in case of large pipe sections. Position the double ball so that the weld seam is between the two balls.

Additional ball protection with the so-called FFH sleeve means that the ball is permanently protected from sparks when welding under the forming gas.

Städtler+Beck offers a wide range of pneumatic locking ball options to solve every challenge with the right product.

AVAILABLE IN DIFFERENT VERSIONS

Fireproof covers, for stopping pipelines during weldment

Chemical resistant covers

High pressure covers

Inflexible or flexible rods/struts

Different pressure gauges

With or without rubber plugs

Single or double bags

With all commercial connections

With or without valves

If you are unable find the right one or you wish a special size, we offer you a fast and uncomplicated solution on your request.

CHARACTERISTICS OF MATERIALS

Natural rubber (NK) –

Highly elastic, high abrasion

– approximately +60°C

Nitrile (NBR) –

Resistant to the action of oils, especially hydraulic oils, greases, gasoline –

approximately +70°C

EPDM (Ethylen-Propylen-Dien-Monomer) –

Chemical resistance, very good resistance to aging and ozone resistance –

approximately +120°C

Neoprene (CR) –

Oil - Acid resistant, good resistance to embrittlement, weathering, ozone attack and flame resistance –

approximately +80°C

Viton (FKM) –

Temperature-resistant, aging resistance, associated with a very good compression set –

approximately +200°C

These details are for guidance only and are not generally valid.

Please consider that these data apply only as approximate.

The resistance may vary according to the concentration and temperature of the medium.

We will advise you on your choices and provide support to ensure your job is done perfectly.

STILL HAVE A QUESTION, PLEASE CONTACT US

Pipe plugs

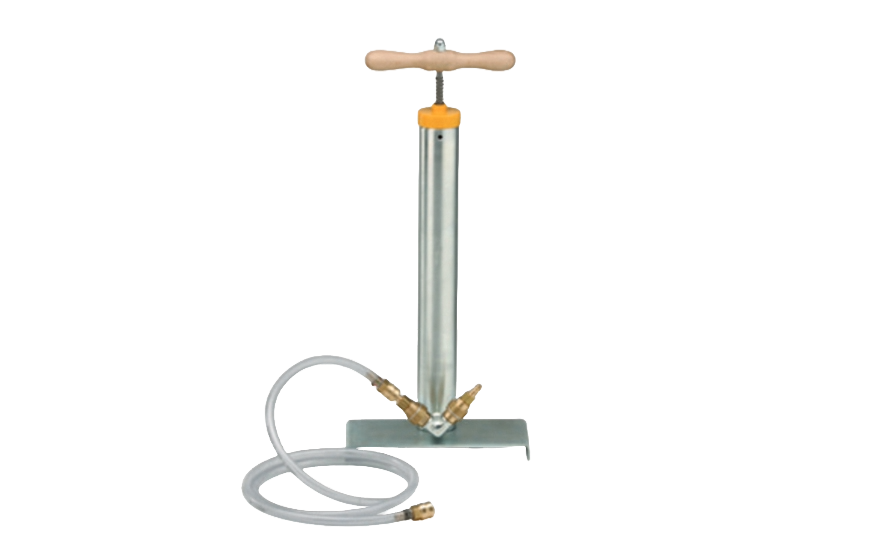

Pipe plugs  Pressure-Suction Pump

Pressure-Suction Pump  Pneumatic multi-size flow-stop bags

Pneumatic multi-size flow-stop bags