- Corrosion protectionNEW

- Non-Destructive TestingNEW

- About companyNEW

- ContactsNEW

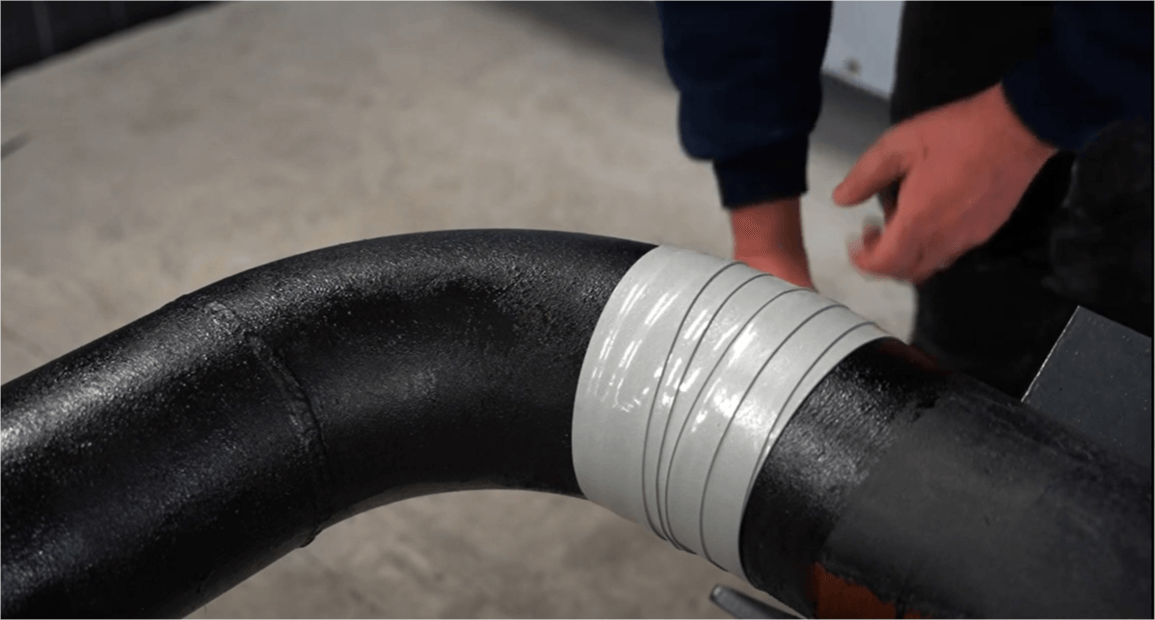

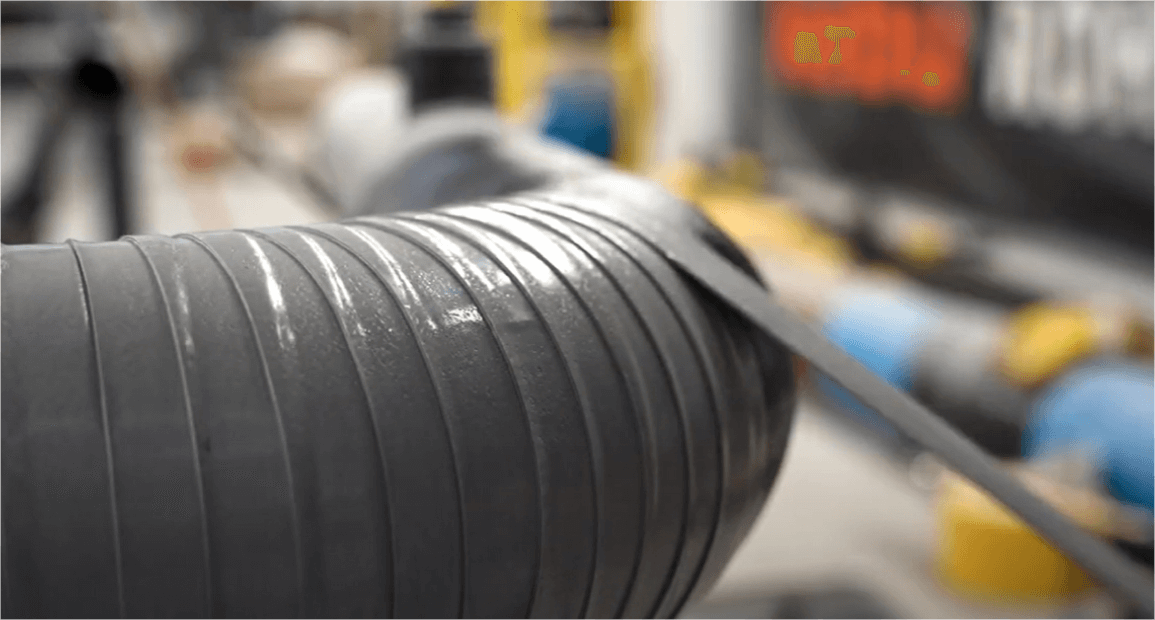

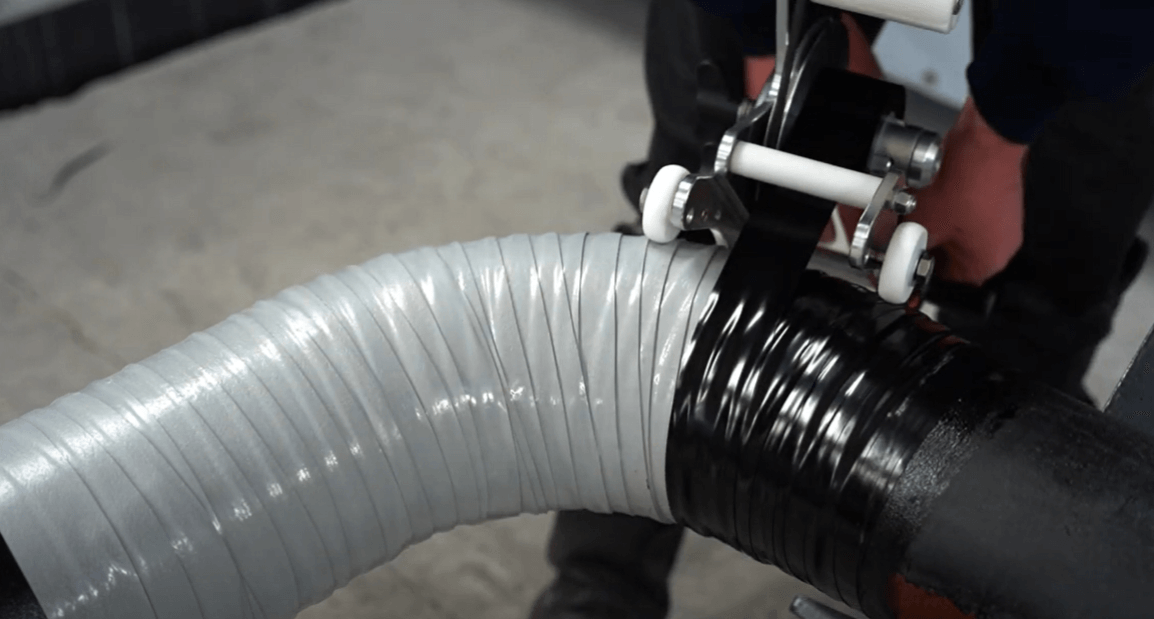

Kebutyl-System C 30 is a two-tape system for corrosion protection of pipelines in accordance with DIN EN 12068, DIN 30672 and IS0 21809-3. Kebutyl-System C 30 consists of a primer Kebutyl-Primer K III, a 3-layer anti-corrosion tape made of viscoelastic adhesive applied on a polyethylene backing film Kebulen-Tape 1,5 H (inner layer) and tape Kebulen-Foil PE 0,40 (mechanical outer layer). Kebutyl-System C 30 meets the requirements of load class C at a maximum operating temperature of 30oC. The co-extruded inner layer Kebulen-Tape 1,5 H creates a strong cohesive bond with the primed steel surface and the mechanical outer layer. At the spiral overlap it fully amalgamates and forms a “sleeve-type coating”.

DIN-DVGW-Reg.-Nr.: NV-5180BL0284

Kebutyl-Primer K III - is a solvent free coupling agent based on butyl rubber 2 layers 3ply Kebulen-Tape 1,5 H - (1 wrap with 50 % overlap) 2 layers Kebulen-Foil PE 0,40 - (1 wrap with 50 % overlap)

Fully amalgamating overlapping areas Forming a “sleeve-type coating” Impermeable to oxygen and moisture Resistant to soil stress Co-Extrusion technology Superior in-ground performance

Kebutyl-System C 30 is a cold applied corrosion protective system used for the coating of buried or immersed steel pipelines Kebutyl-System C 30 is used for coating in the welded seam area, coating fittings and branches of complex configurations, as well as for pipeline recoating. The Kebutyl-System C 30 is compatible with factory coatings of PE, PP, epoxy resin, PU and bitumen. The Kebutyl-System C 30 is compatible with factory coatings of PE, PP, epoxy resin, PU and bitumen.